Welcome, from sunny Australia!

Differentials, Tailshafts, and Brakes

Differentials, Tailshafts, and Brakes

Shortcut to -

LSD's

Tailshafts

Brakes

Differentials

WAY too much to talk about here, but

one clever trick that helps the handling of a live axle read end car

is to bend the diff housing. You have to put them into a very large

hydraulic press and rig up some strong bracing to hold them, but it is

possible to get a half degree or so negative camber into the housing an

also a millimetre of toe-in. It may not sound like much, but those

small amounts will helps immensely to make the car more stable at all

times. It's also rather surprise just how far you have to bend the diff

housing to make it stay bent!!

There's nothing terribly tricky about the internals of a differential, so all you have to do is to set up the clearances as per the manual.

One thing that's always annoying is

getting the darn filler and drain plugs undone! They always seem to

strip the head ... The way out of that is to weld on a large nut

to the plugs so you can get a big spanner to undo the little darlings

...

BTW, when you weld the nut on, make sure

that you remove the EFI computer from the wiring loom and also

disconnect the battery. Don't say I didn't warn you.

Limited

Slip Differentials

One good gadget to have in the rear end is

an LSD, or Limited Slip Diff. What this thing does is create a link

between the rear wheels (or front wheels, in a FWD car, and often

between the front and rear wheels as well in a 4WD) so that instead of

letting them spin freely with respect to each other, they have a

certain amount of friction. I'll be talking about three types, but only

two in any detail. The cheapest and certainly the nastiest to drive is

what we call in Australia as the 'CIG Locker'. What this means is that

the centre of the diff has been welded up (By using an oxy welder,

almost invariably powered by CIG gasses, gettit??) so that the rear

wheels are solidly locked together. This makes the car very hard to

turn around slow speed corners, as the inside tyre wants to rotate at

the same speed as the more heavily loaded outside, and so tends to push

the car in a straight line - big time understeer! If you have enough

power, then you can get both rears spinning nicely, and so create and

control the oversteer that will then develop. You really have to drive

the car on the throttle a lot more than a 'normal' car, and so they can

be a quite tricky unless you get used to it quickly.

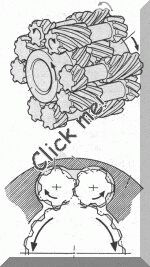

Possibly the best LSD of all is the Torsen 'torque sensing' type. They are a very good thing, as they always spread the torque evenly between both wheels at all times, so even if you have one tyre on ice and the other on sandpaper, both wheels will spin evenly. There are two types of Torsen, and this is a Type One.

The Type One Torsen LSD that does a pretty good job and is available on a lot of Toyota cars from about the mid 90's onwards. This is an exploded view of a complete diff -

Here's a view of the LSD gears themselves -

And finally, a view of the action that the LSD gears take to provide the LSD effect -

Tailshafts

Fortunately, not a lot to be said about

tailshafts. There's only a couple of tricks to them, and by far the

most important one that people often don't know is -

- The universal joints at either end MUST be

lined up exactly parallel to each other. By this I mean that the cups

at

the end of the tailshaft must be in line as you look down the

tailshaft.

If this isn't the case, then the tailshaft will destroy itself and the

universal joints rather quickly! The reason for this is because as

they spin around uni-joints don't follow a constant rpm. This

increases with the deflection angle, so if you have them out of line

on your tailshaft then one end is trying to do one rpm, and the far end

is trying to do a slightly faster or slower one, every

revolution! This can sometimes be felt as an incurable vibration

in the car which gets worse as the speed builds up.

- Try to keep the diameter as small as

possible to reduce rotational inertia. As a general rule though, the

smaller the diameter then thicker the tailshaft tube metal has to be,

partly negating the advantage of a smaller tube.

- The correct length is when the car is at

ride height, the front yoke's back face of the tailshaft is flush with

the back of the gearbox housing. Make sure that there is at least 15mm

to 20mm of further travel in both directions (In & out) of the

tailshaft at full bump & droop on the rear suspension.

- Most modern cars have a two piece

tailshaft. This is only to reduce vibration. (Have a look at one if

you get a chance - One part is always longer than the other to reduce

harmonic vibration. Clever!) For a performance car, this is a

waste of time, and it should be replaced with a one piece unit.

- A lot of modern tailshafts also have the

uni-joints peened in so they can't be changed an so you have to buy a

new tailshaft, at great expense. Not so - Just take it to a decent

engineering shop and get them to re-fit the tailshaft with normal,

replaceable type uni's. The cups that sit in the yokes will have to be

bigger than they were, but that's no big deal compared with the

alternative ...

- A universal joint is ok when it shows no

signs of 'feeling tight' when you work it around with your hands. If

it feels the slightest bit tight or overly 'loose' at any point, then

change it.

- There are types of tailshafts that have

the uni-joints held in with small U-bolt type devices. These are junk,

and should be replaced with fully enclosed (The metal goes all the way

around type) yokes.

Brakes

A much abused device. :)

There are a few ways of increasing braking

power -

- Bigger discs. A bigger disc, even with no

other changes, will increase stopping power by quite a bit. They do

this by increasing the leverage effect that the brakes have on the

wheel. If you have a 9" disc and go up to an 11" disc, you've just

increased your braking power by a good 22% (5.5" effective lever

arm compared to a 4.5" effective lever arm)

- Four spot calipers. They give a much more

even spread of pressure on the brake pads, and so make the pad work

more efficiently. The reasons for this are that the twin pistons per

pad are pushing over a wider base than a single piston ever could, and

the four piston calipers are inherently more rigid than a two spot or

single pot slider caliper is. The better four spot calipers have

differential sized pistons, ie, the 'front' piston is bigger than the

'rear' piston. (I'll explain why shortly)

- Better pads. Modern pads are bloody

fantastic. Price = Performance though, so how fast do you want to stop?

What other variations in brakes do -

- Twin calipers. Used to get more pad area

on that brake, and usually has one caliper at the front and the other

in the back. Not often used.

- Ventilated discs. The gap in the middle

does a couple of things for the same result. The main reason is to

give the disc double the surface area to help it dump its heat into

the atmosphere. The other thing the gap does is to use the vanes

to pump (centrifuge) air through the gap to help dump heat faster.

- Drilled discs. Exactly the same reason as

a ventilated disc, but not quite as good. The size of the holes in the

disc is worked out so that the surface area of the cylinder they make

is larger than the hole they make in the disc, and so create a greater

surface area overall to help cooling. The other advantage is that the

holes help the plasma hot gasses from the pads escape somewhere.

- Slotted discs. No extra heat dissipation,

but a slot that passes over the pads to help the hot gasses escape.

The slots need not be put on the disc like spokes on a bike wheel, but

can simply be a slot that goes across the disc from one side to the

other side, just clearing the inner running surface of the disc.

As pads wear down, they will become

tapered. This is because as they are applied the disc heats up and

part of that heat is transferred to the pad itself. The problem is

that the heat is not transferred equally - The outer part of the pad

(The part closest to the outside of the disc) gets hotter because the

physical speed of the disc is higher there than it is towards the

centre.

The same goes for the part of the pad that

is last to touch the disc as it goes past - The disc is somewhat

warmer at that point than it is as it first touches the pad, and so

the pad wears faster at that point.

Some of the taper problem can be relieved by

making the discs bigger (The difference in speed between the inner and

outer parts of the disc is lessened) and using a decent four spot

caliper. I mentioned before that the better ones had different sized

pistons - This so the front of the pad gets pushed onto the disc harder

than the rear, thus reducing taper.

In any case, if you have tapered pads

they must be milled flat again or thrown out. It's that simple!

I guess that the above picture answers your question - It's a picture of Damon Hill's Jordan Formula One car, under heavy braking. They use carbon-carbon brakes, which means that the disc pads and disc rotors are made from a carbon fibre matrix composite. They don't work very well when cold, and so have to be used a few times to get up to a good temperature. (~800°C)

On a slightly different track, one good trick I've learned when bleeding brakes is to use a different coloured fluid so you know when the new fluid has gone through the system. Good quality fluids are usually available in either clear, red, or green colours, thus making the job easier.

Speaking of hydraulic fluid, I was asked

recently to explain how to pick the correct master cylinder and brake

piston sizes.

When it comes time to selecting the size of

the master cylinder (I'm assuming that you'll be going for the single

master cylinder/balance valve option) you really only have a

choice of the aftermarket sizes between about 1/2" and 3/4", and they

usually go up in 1/16" increments. The most common size is usually

13/16", however. The 13/16" ones are often coupled with a vacuum

booster, and that's why they're so big. (The vacuum helps you push the

pedal, etc) If you go for a single cylinder, then you'll also

have to, by Law and common sense I believe, have to have one that has

twin (hydraulically separate) outputs. These can be commonly found on

the vast majority of modern cars.

The rules for master cylinder sizes are

simple - The bigger you have them, the harder you have to push the

pedal, but the less it moves. (Eg, the pedal in my racing moves

perhaps 1/4", then goes almost solid - I run fairly large master

cylinders)

The rules for the brakes themselves are

similar - If they have a large piston in them, then for the same given

brake line pressure they will have more clamping pressure on the disc,

thus giving better retardation. But they will also have a longer pedal

travel.

Getting the balance between having the right

size master cylinder and brake piston can be difficult, and it may take

some fiddling. It may seem a bit 'slack', but I would suggest that the

best way to get good brakes right from the start is to simply copy

some-one else's that is known to work well. Don't take their word for

it either - Drive the car to try it for yourself.

Another factor is the brake pedals' pedal mechanical leverage. It is typically about 4:1 to 5:1. Similar rules to the cylinder sizes, of course - The longer the pedal, the better the brakes work but the more the pedal moves. I personally much prefer a solid pedal that you have to push hard on, rather than a soft-ish one that moves a lot. I strongly believe that it gives you much better feel, and so control the brakes right 'on the limit' very accurately.

Back to the Drivetrain - Gearbox - page

For more motorsport links, try the motorsport section on my links page.

Back to the Index page

Page & contents where applicable © Bill Sherwood