Welcome, from Sunny Australia!

Drivetrains- Gearboxes, diffs, tailshafts, and brakes.

Drivetrains- Gearboxes, diffs, tailshafts, and brakes.

Diffs, tailshafts, and brakes are on the next page.

Gearboxes

Your car has to operate over a wide range of

speeds, and the engine can not alter it's revs by enough to cater for

that range of speeds, so the engine's torque must be passed through two

stages to get it to the point where we can use it practically.

The first stage is the gearbox. We need for

the car to be able to move off from a standing start, and then

accelerate to (ultimately) a high speed. To do this, the gearbox has a

set of gears in it that we can engage to vary the output revs compared

to the input revs. Ok, that's simple stuff. How can we make our car go

better by fiddling with the gearbox then?

You have no doubt noticed that whenever you

change up gears, the revs drop. An example might be going from 3rd gear

to 4th gear in a Toyota T-50 gearbox at 6,000rpm will make the revs drop

to about 4,300rpm. Whilst this is fine for an unmodified road engine, in

a performance engine this may be an unacceptable rev drop. In the

gearbox in my racing car, doing exactly the same sort of shift up would

drop the revs to only about 5,200rpm. This has several effects -

- The revs are kept higher, so there is less

chance of 'falling out of the useful power band'.

- There's less of a rev drop, so the engine

doesn't have to slow down as much when changing gears.

So how do you go about making the gears

'closer together' in your gearbox. Well, actually it's pretty easy - All

you have to do is throw a LOT of money at it, and it'll happen.

There are only two ways to get a close ratio

gear set for your gearbox.

METHOD #1.

Buy a set from your cars manufacturer, eg,

with a Toyota T-50 gearbox, you have all of these ratios available to

you. The last two are the close ratio gear sets, and cost about US$1500

each!

| Standard |

Part #33030-AE811

|

Part #33030-AE851

|

| 1st 3.584:1 |

1st 2.341:1

|

1st 2.630:1

|

| 2nd 2.022:1 |

2nd 1.607:1

|

2nd 1.891:1

|

| 3rd 1.384:1 |

3rd 1.195:1

|

3rd 1.384:1

|

| 4th 1:1 |

4th 1:1

|

4th 1:1

|

| 5th 0.861:1 |

5th 0.886:1

|

5th 0.861:1

|

METHOD #2

Make up what you want. This is a difficult

thing to do, and takes a lot of time, patience, and money. The average

gear machinist (If there is any such thing!) will charge about

Aus$400 - Aus$500 per ratio. In my racing car's gearbox, I had

to get four ratios changed, so it cost nearly $2,000 just for a set of

small gears. There is no way around this at all, and it is the price you

must pay for the 'perfect' gearbox.

A quick word on gear machinists - There are

good ones and there are bad ones, and not much in between. They are also

damn hard to find, regardless of the quality of their work. The best

ones are usually so back-logged with work that it can take up to SIX

MONTHS to get you gear set done. (No! I'm not joking!) The best in

Australia, and in fact one of the best in the world is Peter Hollinger.

I got a gear set from him for my Toyota K-40 gearbox back in the late

80's, and I was lucky that I only had to wait just over five months for

him to finish them. (It was worth the wait, too) Peter is

now only working for the top teams in Australia and the rest of the

world, and so does not do any work for club level people such as myself.

There is another excellent gear cutter in

Australia, called Ivan

Albin, and he works out of a shop at Ballarat in Victoria.

|

Here's an example of gears welded to a shaft. You can see an original gear on the right, and two close-ratioed gears on the left, including the weld that's used to hold them in place. |

Ok, still want to go on?

This is where it gets tricky.

I think that the best way to explain how to

figure out how to pick what gears you want is to first explain how the

gearbox works. So -

-Click on the picture below and save

it. Better still, print it out so you can look at it and read these

words.

Look at the gears along the bottom of the box. There's five, right? That means there's six gears! Don't panic - I'm including reverse.

Let's trace the path of the torque as it

travels through the gearbox, from right to left in a couple of different

gears.

1st gear - The engine torque comes through

the Input Shaft, and (looking at the picture and making an educated

guess) multiplied by about 40%. By this I mean that the teeth on the

Input Shaft have a ratio of about 30/42, so if the engine was doing

4,200rpm then the Lay Shaft would be doing 3,000rpm. This is very

important, as the Input Shaft ratio controls the ratios for ALL of the

gears in the gearbox. (Except 4th, of course)

Looking along the Lay Shaft, we can see that

there is five gears shown. (Remember that the left-most gear is the

Input Shaft gear, and so can't be picked when shifting) The

smallest gear (Fourth from the left, just above the 'e' in "view") is

the actual 1st gear. See how much smaller it is compared to the gear it

meshes with on the Main Shaft? That's because it has to reduce the rpm's

even further, and so multiply (increase) torque again. In this case, to

a final ratio of 3.25:1.

2nd gear - The engine torque still goes through the Input Shaft and still travels along the Lay Shaft, but not quite as far this time. The actual 2nd gear is the third one long from the left. (Just above the 'a' in "cutaway") See how this gear is bigger than the 1st gear? This is because it doesn't have to reduce the rpm's as much, and hence increase the torque. 2.043:1

3rd gear - Same again, but the torque goes up through the first gear to the right of the input gears. Note how that gear is nearly the same size as the one above it on the Main Shaft? Remember how the Input Shaft gears reduced rpm and increased torque by about 40%? Well, surprise, surprise, the 3rd gear final ratio in a W-50 is 1.397:1.

5th gear - Still all the same, but now go to the very far right hand end of the Lay Shaft. See how the Lay Shaft's gear is bigger than the Main Shaft gear is and also slightly bigger than the Input Shafts as well? That's because 5th gear is an over drive, and so makes it an overdrive gear. 0.853:1

4th gear - I've left 4th gear until last. It's also the easiest; The torque come in the Input Shaft, and since the Input Shaft is locked to the Main Shaft, the torque is transmitted straight down the Main Shaft.

Reverse gear - It isn't shown in the

picture, but it lives next to fifth gear, just to the left. (Both

reverse and 5th gear live in a part of the gearbox called the Extension

Housing) It works exactly the same way as the 1st, 2nd, 3rd, and

5th, but there is another gear between the Main and Lay shafts to

reverse the direction of rotation, thus giving reverse gear. On some

gearboxes (Eg, the Toyota K-40 & K-50) this 'idler' gear is moved to

engage reverse, whilst others (Umm .. just about every other one I can

think of) have a 'primitive' version of a synchromesh to engage the

reverse gear, because the idler gear is engaged all the time.

(A quick bit of trivia - This is why you

have to be dead stationary when picking reverse in a K-40/50 gearbox,

but with a, say, T-50, you can pick reverse with the car moving

backwards at a reasonable speed without 'crunching' the box)

Ok, now that all of that is out of the

way, lets turn the W-50 in the picture into a close ratio racing box.

First off, you have to count the teeth on

all of the gears.

Lets call the Input Shaft 30/42

I'll stay with 3rd gear for now to keep

things simple. We decided that 3rd gear had pretty close to the same

number of teeth, so we'll make those gears with 36 teeth each.

If we change the number of teeth on the

Input Shaft to 31/41, then the input ratio has gone from 1.4:1 to

1.322:1. So what? Well, with no other changes, we have now made 3rd gear

1.322:1. A useful change, no doubt.

What's happened to the rest of the gears

then?

1st gear is also 'closer' - It's now be

about 3.06:1 (3.25/1.4 x 1.322)

2nd gear would be about 1.93:1 (was

2.043:1, so closer)

3rd gear 1.322:1 (was 1.397:1, so

closer)

4th gear is unchanged, as it's unaffected by

the Input Shaft ratio changes.

5th gear is now 0.805:1 (was 0.853:1

so ...

... Hang on! What's going on here? - 5th

gear was 0.853:1, and now it's 0.805:1 - That's wider than

it was!

Well, that's the unfortunate fact of life

with overdrive gearboxes. If you make the gear over 1:1 closer,

then you also make the gears under 1:1 wider. Bit

of a bugger that, but we're stuck with it. This means that whenever you

change the Input Shaft ratio, you also have to change the overdrive

gears, with an additional expense of $400 - $500. :(

These teeth changing tricks can be

applied to any pair of gears in the gearbox, ie, if you just want to

alter one ratio, then you can do just that by modifying that gear

itself. But this is uncommon - Most people always change the Input Shaft

ratio, and so close up all the ratio's to make the gearbox, well, closer.

We've seen what happens when you alter the

Input Shaft by a small amount, so how far can you go? Well, you can do a

surprising amount in fact. As long as the two gears, any gears, are

still spinning off the same shafts then you can make their diameters

anything you like. Common sense does apply though, ie, if you start off

with a pair of gears with 30/42 teeth, then you can't have a set of

gears with 10/62 teeth. All this leads us to ...

Gearbox Trick #1

You've got 30/42 teeth gears. You can go for

42/30 if you like or need, but they must add up to (in this case alone)

72 teeth. But DO they?

No! In practice you can have 29/42, 31/42,

30/41, or 30/43. What this means is that you can go one tooth either

side of what the gears would normally add up to. The best way to check

is to add up all the pairs of gears in the gearbox - You'll find that

they are all to within a tooth of (in this case only) 72 teeth. Some

will add up to 71, and others maybe 73. This is a handy trick is you

want to get really accurate with picking your new ratios.

By using this trick, the K-50 in my racing

car went from the standard ratios of 3.7:1, 2.2:1, 1.38:1, 1:1, and

0.865:1 to the terribly raceable 2.33:1, 1.66:1, 1.38:1, 1.17:1, and 5th

of 1:1. (How did I get 5th 1:1? By being sneaky, as usual - read the

story of it on the My Racing

Car page)

So you've added a few sets of new gears to your gearbox, and you want to make sure that they don't break, 'cause damn are they expensive! How about ....

Gearbox Trick #2

If you're going to add completely new gears

to your gearbox, then why not get them made up a bit wider to help

handle the extra torque of you grunty engine? The gear pairs that have

been altered in my K-50 are nearly 3mm wider than the original Toyota

ones.

You've heard that racing gearboxes are

often straight-cut to make more power. This much is true, but it's at a

price - A HELL of a racket and a bit of a decrease in strength. The

extra noise comes from the straight gears meshing together, (The

familiar 'supercharger' type whine) and less strength because a more

normal road type helical-cut gear (One that has the teeth at an angle)

is actually stronger. (In a straight-cut gearset, there is only one

tooth engaged at a time, whilst the helical gearset has around 1.5 teeth

engaged at any one time) The reason the straight-cut gearboxes make more

power is because with helical-cut gears the gears try to push themselves

away from each other in the same direction as the shafts they run on.

Hence, all road gearboxes have small thrust bearings on each end of the

shafts to take the load of the shafts trying to escape out the far end

of the gearbox casing. All that lateral effort, of course, is power

being wasted and so a lot of racing teams use straight-cut gears to

minimise power loss through the gearbox.

So, it may be no surprise that there's ....

Gearbox Trick #3

If you have the chance to pick a new set of

gears for your gearbox, then it's probably a good idea to specific a

shallower helical-cut gear than the standard ones come with. Somewhere

between straight-cut and helical-cut is a good thing. It's a reasonable

compromise between the power gain of a straight-cut gear set and the

extra strength of a helical-cut set.

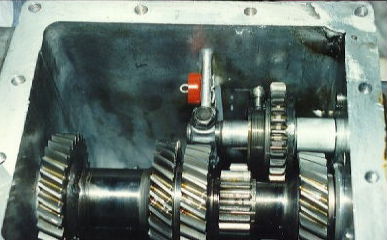

Here's a picture of the internals, and if you look carefully you can see all of the 'tricks' that I have mentioned.

Back to the Index page

Page & contents where applicable © Bill Sherwood